new upper intake manifold testing done : available for purchase soon

#51

.

Dave, would you do the rounding of the ports after the flanges are made?

What size AL again?

Thought about it, you don't need to send me anything, I can just use a gasket (if you're matching to fel-pro) and he can make a copy. Might take a week or so, he just got a big order from Motorola to make stainless injection molds for cell phones (he works with like .000001 tolerances) and I think he's going in at 12hr on and 4hr off for a few days.

#52

Supreme Member

Thread Starter

iTrader: (3)

Join Date: Dec 2005

Location: Sayreville NJ

Posts: 2,472

Likes: 0

Received 0 Likes

on

0 Posts

yeah matching to a felpro gasket would be fine,getting the radius cnc'ed would be best,the radius is hard as hell to machine cause of the odd shaped port,having it done on a cnc would keep the radius uniform and even all the way around,which would make the port flow even better. a good radius at the entry could mean 2x the flow compared to no radius or an ununiform radius.

off the top of my head i belive the flanges were 3 inch wide and 9.250 long by .500 thick.though i can let u know first thing in the morning when i get to the shop if u can print out some pics so he can see what mine looke dlike with the radius and stuff.

but if he cant do it i can do it

off the top of my head i belive the flanges were 3 inch wide and 9.250 long by .500 thick.though i can let u know first thing in the morning when i get to the shop if u can print out some pics so he can see what mine looke dlike with the radius and stuff.

but if he cant do it i can do it

#56

Supreme Member

Thread Starter

iTrader: (3)

Join Date: Dec 2005

Location: Sayreville NJ

Posts: 2,472

Likes: 0

Received 0 Likes

on

0 Posts

firstfirebird, the flanges are 2.500 wide x 9.250 long x .500 thick.

just have him center the gasket on the material,it wont work if he trys using material not as wide,it has to be 2.5inch wide.

just have him center the gasket on the material,it wont work if he trys using material not as wide,it has to be 2.5inch wide.

#57

Supreme Member

Join Date: Oct 2001

Location: NWOhioToledoArea

Posts: 8,113

Likes: 0

Received 5 Likes

on

5 Posts

Car: 86-FireBird

Engine: -MPFI

Transmission: T5

Axle/Gears: 3:42

Dave this is heading into the dust like all good projects here. Gotta cut your cost usually on labor. Don't pay your self but min wage.

I do better doing thing cheap with hi volume then to get what I deserve and just get by.

Do some math

you can sell maybe 10 of them over the next 2 years for $400 or sell 100-150 easy for $150 bare raw, 10-20 for $200-$300 if you offer to powdercoat, chrome or maybe get like custom cut pattern top plates to weld on.

I know you deserve $400 for the raw bare intake but volume will pay off in the end. As everyone here is cheap and its why no one bought them $3-500 headers projects that have failed 3-4 times.

Gotta get some jigs made and cut time and cost in half if you wanna really make any money. Trust me I know first hand.

I do better doing thing cheap with hi volume then to get what I deserve and just get by.

Do some math

you can sell maybe 10 of them over the next 2 years for $400 or sell 100-150 easy for $150 bare raw, 10-20 for $200-$300 if you offer to powdercoat, chrome or maybe get like custom cut pattern top plates to weld on.

I know you deserve $400 for the raw bare intake but volume will pay off in the end. As everyone here is cheap and its why no one bought them $3-500 headers projects that have failed 3-4 times.

Gotta get some jigs made and cut time and cost in half if you wanna really make any money. Trust me I know first hand.

#58

Supreme Member

Thread Starter

iTrader: (3)

Join Date: Dec 2005

Location: Sayreville NJ

Posts: 2,472

Likes: 0

Received 0 Likes

on

0 Posts

Dave this is heading into the dust like all good projects here. Gotta cut your cost usually on labor. Don't pay your self but min wage.

I do better doing thing cheap with hi volume then to get what I deserve and just get by.

Do some math

you can sell maybe 10 of them over the next 2 years for $400 or sell 100-150 easy for $150 bare raw, 10-20 for $200-$300 if you offer to powdercoat, chrome or maybe get like custom cut pattern top plates to weld on.

I know you deserve $400 for the raw bare intake but volume will pay off in the end. As everyone here is cheap and its why no one bought them $3-500 headers projects that have failed 3-4 times.

Gotta get some jigs made and cut time and cost in half if you wanna really make any money. Trust me I know first hand.

I do better doing thing cheap with hi volume then to get what I deserve and just get by.

Do some math

you can sell maybe 10 of them over the next 2 years for $400 or sell 100-150 easy for $150 bare raw, 10-20 for $200-$300 if you offer to powdercoat, chrome or maybe get like custom cut pattern top plates to weld on.

I know you deserve $400 for the raw bare intake but volume will pay off in the end. As everyone here is cheap and its why no one bought them $3-500 headers projects that have failed 3-4 times.

Gotta get some jigs made and cut time and cost in half if you wanna really make any money. Trust me I know first hand.

the 2 most expensive things on this manifold are welding,followed by machine work, it takes a few hours to weld this thing together,to be sure everything is square and it dosent warp.

im gonna try to get the price down to the mid 200 range like i had originally thought it would be

#59

Supreme Member

Join Date: Oct 2001

Location: NWOhioToledoArea

Posts: 8,113

Likes: 0

Received 5 Likes

on

5 Posts

Car: 86-FireBird

Engine: -MPFI

Transmission: T5

Axle/Gears: 3:42

Need to find a wood working friend to help show ya how to make a jig rig for the flanges. Can easily use a modfyied router bit to do the finish work on the holes once most of the waste is cut out. aluminum and wood are so similar.Top parts rides on a blank copy with a bearing and ya can easily dup the flanges quick. Wood working guys who are into it always build jigs to reproduce work.

Off topic but speaking of wood, craftsmen now has this $300 mini cnc like machine to cut 3d patters into wood planks. Could easily be switch to aluminum if you can slow it down. Does real fancy patterns almost like a water jet too.

Off topic but speaking of wood, craftsmen now has this $300 mini cnc like machine to cut 3d patters into wood planks. Could easily be switch to aluminum if you can slow it down. Does real fancy patterns almost like a water jet too.

#60

Need to find a wood working friend to help show ya how to make a jig rig for the flanges. Can easily use a modfyied router bit to do the finish work on the holes once most of the waste is cut out. aluminum and wood are so similar.Top parts rides on a blank copy with a bearing and ya can easily dup the flanges quick. Wood working guys who are into it always build jigs to reproduce work.

Off topic but speaking of wood, craftsmen now has this $300 mini cnc like machine to cut 3d patters into wood planks. Could easily be switch to aluminum if you can slow it down. Does real fancy patterns almost like a water jet too.

Off topic but speaking of wood, craftsmen now has this $300 mini cnc like machine to cut 3d patters into wood planks. Could easily be switch to aluminum if you can slow it down. Does real fancy patterns almost like a water jet too.

#61

Supreme Member

Thread Starter

iTrader: (3)

Join Date: Dec 2005

Location: Sayreville NJ

Posts: 2,472

Likes: 0

Received 0 Likes

on

0 Posts

heya firstfirebird, if u can get me flanges i can do the manifolds for around 250 each,depending on how much the flanges cost.its the flanges that drive the price up.

the problem with using a router is if it dosent leave a nice smooth finish or a nice radius,there still gonna be time involved with cleaning them up and grinding.but hopefully firstfirebird can get these cnc'ed for me

the problem with using a router is if it dosent leave a nice smooth finish or a nice radius,there still gonna be time involved with cleaning them up and grinding.but hopefully firstfirebird can get these cnc'ed for me

#62

heya firstfirebird, if u can get me flanges i can do the manifolds for around 250 each,depending on how much the flanges cost.its the flanges that drive the price up.

the problem with using a router is if it dosent leave a nice smooth finish or a nice radius,there still gonna be time involved with cleaning them up and grinding.but hopefully firstfirebird can get these cnc'ed for me

the problem with using a router is if it dosent leave a nice smooth finish or a nice radius,there still gonna be time involved with cleaning them up and grinding.but hopefully firstfirebird can get these cnc'ed for me

He can cut over 1/2" of AL on his lathe in one pass and no cooling! He is enjoying making this custom stuff, he gets bored after making the same stuff for 20yrs, haha.

#63

Supreme Member

Join Date: Jul 2001

Location: BFE, MD

Posts: 4,461

Likes: 0

Received 0 Likes

on

0 Posts

Car: 13 Ram 1500/ 78 Formy

Engine: 5.7 / 7.4

Transmission: 6sp / TH350

Axle/Gears: 3.55 posi / 3.23

gotta love them G codes, or are they called something else now? it's been like 13yrs since I did any CNC ops.

#65

Supreme Member

Join Date: Oct 2001

Location: NWOhioToledoArea

Posts: 8,113

Likes: 0

Received 5 Likes

on

5 Posts

Car: 86-FireBird

Engine: -MPFI

Transmission: T5

Axle/Gears: 3:42

Well thing here is to get Dave set up doing his own mill work so it cost next till nill, just material cost. And Dave yea a router will it get almost baby smooth like a CNC, wood is very similar. But once a jig is made and ya do a holesaw cut to get most of the waste I bet it don't take but 30 mins to knock two out. Do them while ya watch TV.

#66

Well thing here is to get Dave set up doing his own mill work so it cost next till nill, just material cost. And Dave yea a router will it get almost baby smooth like a CNC, wood is very similar. But once a jig is made and ya do a holesaw cut to get most of the waste I bet it don't take but 30 mins to knock two out. Do them while ya watch TV.

Gumby, you said $300 for a CNC from Craftsman?! Gotta check this out...

.

EDIT : Found what you are talking about, the CNC is $1,900.

http://www.sears.com/sr/javasr/product.do?cat=Bench+Power+Tools&pid=00921754000&vertical=TOOL&subcat=Jointers%2C+Planers+%26+Shapers&BV_UseBVCookie=Yes

However thay do have an attachment for a drill press that turns it into a mill for $219.

http://www.sears.com/sr/javasr/product.do?cat=Power+Tool+Accessories&pid=00927593000&vertical=TOOL&subcat=Drill+Press&BV_UseBVCookie=Yes

Last edited by firstfirebird; 01-25-2007 at 06:18 AM.

#67

Senior Member

Join Date: Aug 2005

Location: Connecticut

Posts: 767

Likes: 0

Received 0 Likes

on

0 Posts

Car: 2005 Lincoln LS, 83' Z28

Engine: 242 DOHC and an empty engine bay.

Transmission: 5R55S, T5 soon to be auto

Axle/Gears: 3.58s and soon to be 4.10s

Hey Dave not to jack your thread er anything but if I made a blueprint for a custom plenum would you be able to make it for me. I wouldnt mind paying the $500 or whatever amount it would be as long as its solid and could stand up to about 15psi. Let me know man and good luck selling the ones you designed already.

#68

Supreme Member

Thread Starter

iTrader: (3)

Join Date: Dec 2005

Location: Sayreville NJ

Posts: 2,472

Likes: 0

Received 0 Likes

on

0 Posts

Hey Dave not to jack your thread er anything but if I made a blueprint for a custom plenum would you be able to make it for me. I wouldnt mind paying the $500 or whatever amount it would be as long as its solid and could stand up to about 15psi. Let me know man and good luck selling the ones you designed already.

ok guys firstfirebird has come threw with getting me cnced flanges ( so thank him for the huge price drop)

prices will be as follows

#1 bare raw finished manifolds ( bare aluminum) 250$'s

#2 powdercoated manifolds 250$'s +25-75$'s depending on the powder coating color u chose.Colors range from normal basic colors to pearls and colorchangin i.e chamelon

#3 ceramic coated250$'s + 80-150$'s depending on color

colors range form standard jethot color to blue,turbo x and a few others

ill post up links to some color charts when i get the chance.

ok now thats done with who is in for one?

#71

Member

Join Date: Oct 2004

Location: Moberly Missouri

Posts: 253

Likes: 0

Received 0 Likes

on

0 Posts

Car: 1985 Firebird

Engine: 3.1L (planning for a turbo)

Transmission: 700R4

Axle/Gears: 3.42

for 250 I'll probably get one. half to get some holliday bills cought up first. (and buy a rebuild kit, and turbo+ MTC-5 cam ect..)

#75

Member

Join Date: Oct 2004

Location: Moberly Missouri

Posts: 253

Likes: 0

Received 0 Likes

on

0 Posts

Car: 1985 Firebird

Engine: 3.1L (planning for a turbo)

Transmission: 700R4

Axle/Gears: 3.42

yea if you want to PM me the specs on that and how to get ahold of deltacams that would be great. How well would this cam work on a non-turbo engine? (i plan on adding the turbo later after the inital rebuild and suspension upgrades.)

#76

Supreme Member

Thread Starter

iTrader: (3)

Join Date: Dec 2005

Location: Sayreville NJ

Posts: 2,472

Likes: 0

Received 0 Likes

on

0 Posts

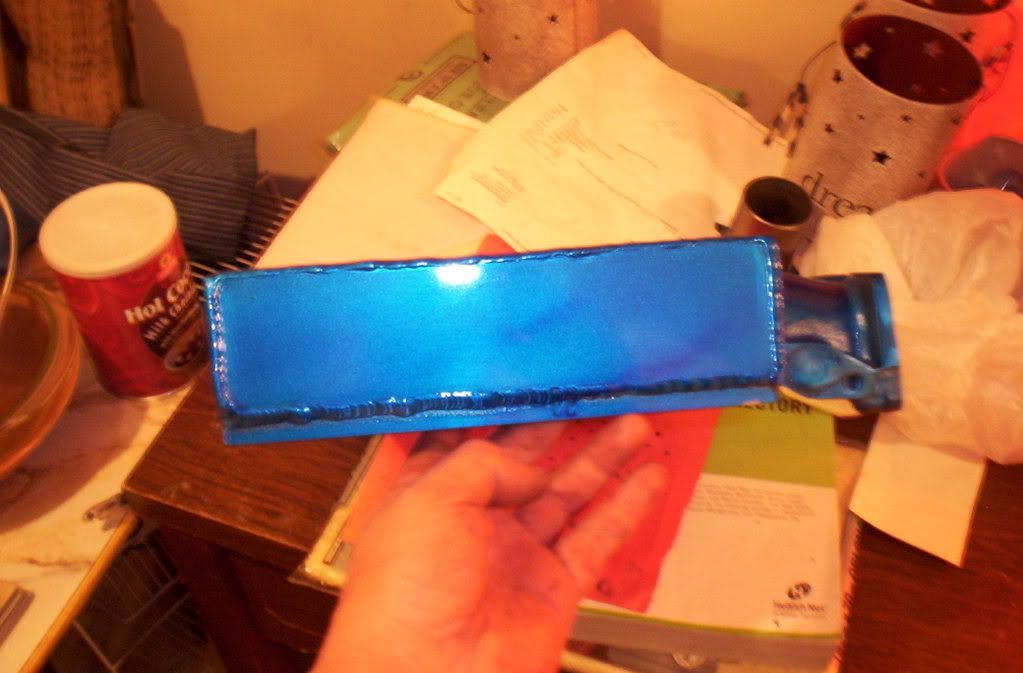

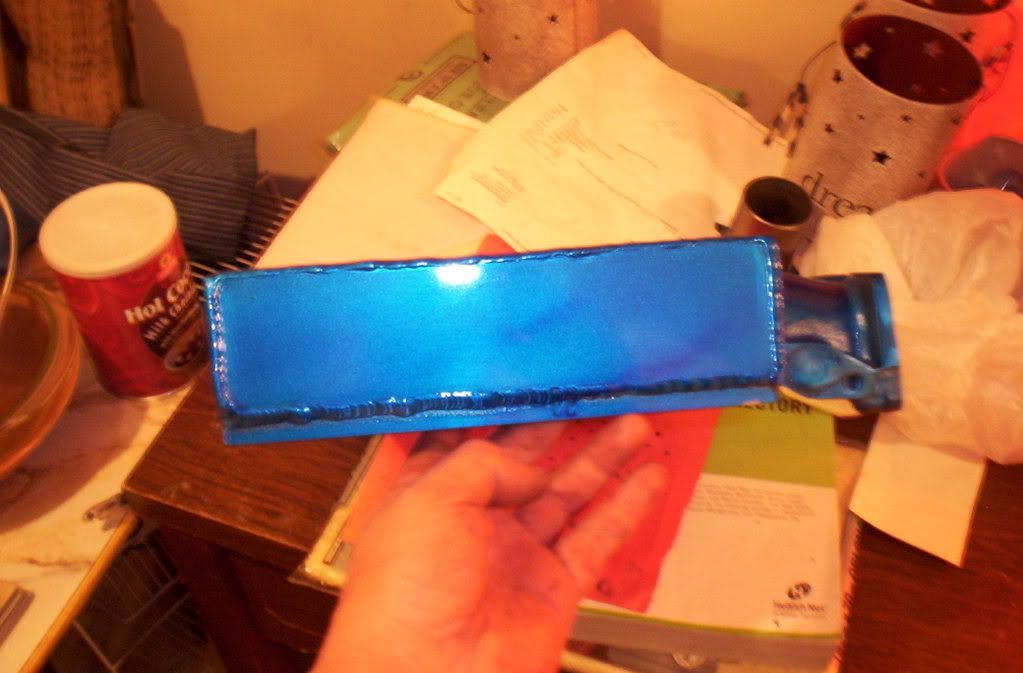

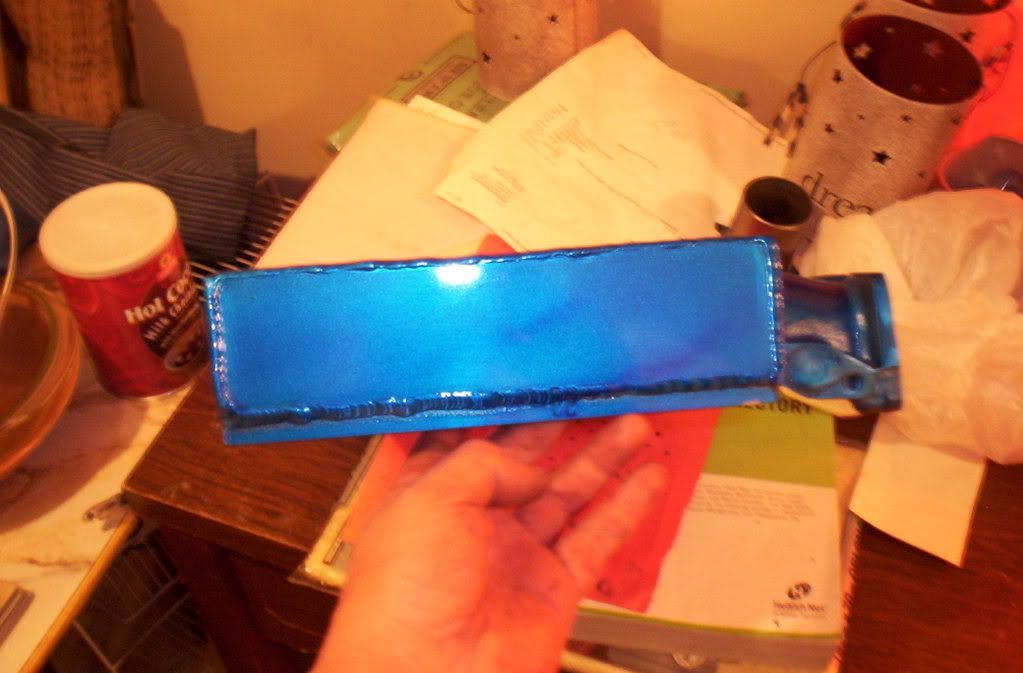

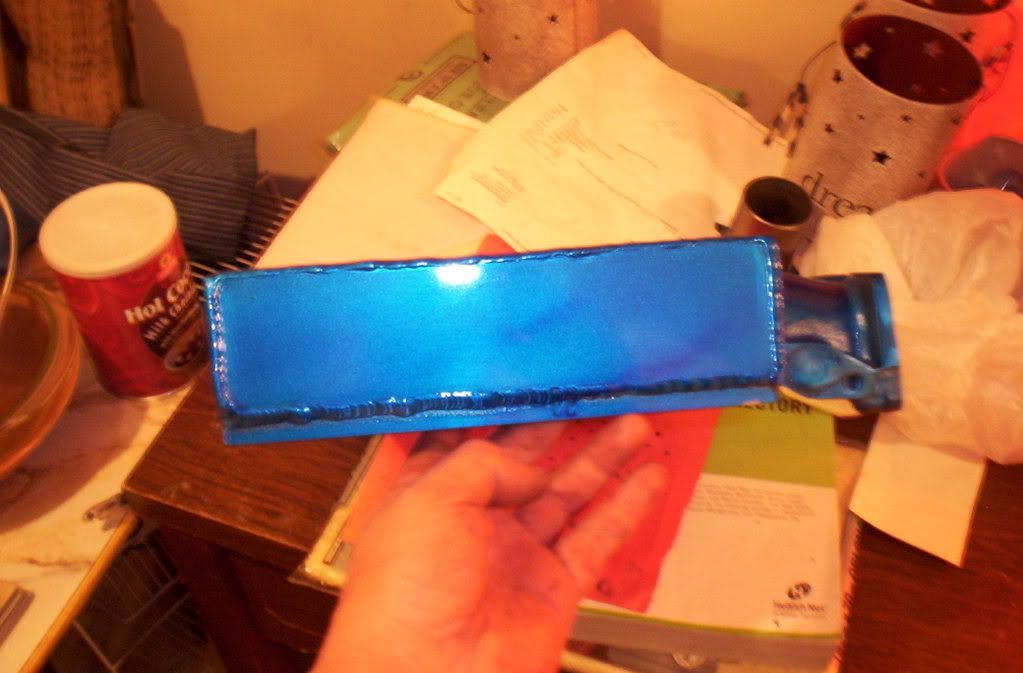

pictures do not do this paint justice, 2 step paint silver metalic base,with translucent blue top coat.

of course i was in a hurry to putit on the car so i had only given the paint 20 mins to set up, so i marked it all up,so i pulled it again today to blast it and repaint it.this time ill let the paint dry a few days before i attempt to reinstall the manifold

of course i was in a hurry to putit on the car so i had only given the paint 20 mins to set up, so i marked it all up,so i pulled it again today to blast it and repaint it.this time ill let the paint dry a few days before i attempt to reinstall the manifold

#77

pictures do not do this paint justice, 2 step paint silver metalic base,with translucent blue top coat.

of course i was in a hurry to putit on the car so i had only given the paint 20 mins to set up, so i marked it all up,so i pulled it again today to blast it and repaint it.this time ill let the paint dry a few days before i attempt to reinstall the manifold

of course i was in a hurry to putit on the car so i had only given the paint 20 mins to set up, so i marked it all up,so i pulled it again today to blast it and repaint it.this time ill let the paint dry a few days before i attempt to reinstall the manifold

That UIM would look good in my car, LOL.

----------

Actually I let it set for 4hrs or more (still put couple of marks), that stuff takes forever to dry!

Last edited by firstfirebird; 02-04-2007 at 01:45 PM. Reason: Automerged Doublepost

#78

Junior Member

Join Date: Oct 2006

Location: MI, in ohio for college

Posts: 82

Likes: 0

Received 0 Likes

on

0 Posts

Car: 91 camaro T-Tops

Engine: L03

Transmission: Borg T5

Axle/Gears: 3.23

this might be a stupid question. But if you're building a custom intake why not use a TPI throttle body? They can flow 800-1000 CFM. Or would it not be worth the time/effort, for the minimal increase. Thought I'd ask though the 12 sec V6 may be the only one needing that improvement.

#79

Supreme Member

Thread Starter

iTrader: (3)

Join Date: Dec 2005

Location: Sayreville NJ

Posts: 2,472

Likes: 0

Received 0 Likes

on

0 Posts

this might be a stupid question. But if you're building a custom intake why not use a TPI throttle body? They can flow 800-1000 CFM. Or would it not be worth the time/effort, for the minimal increase. Thought I'd ask though the 12 sec V6 may be the only one needing that improvement.

as for mine,im going to a ford style tb around 75-90 mm in diamater

#80

Have you seen the Northstar TB's thay're selling on 60*v6? 75MM for $50 shipped. Here's the link...

http://60degreev6.com/showthread.php?t=34483

http://60degreev6.com/showthread.php?t=34483

#81

Supreme Member

Thread Starter

iTrader: (3)

Join Date: Dec 2005

Location: Sayreville NJ

Posts: 2,472

Likes: 0

Received 0 Likes

on

0 Posts

i dont know if thosw will work with the 3rdgen ecms(idle air control motor)

anyways did u use the metal cast paint from duplicolor? thats what i used and must say for the hurry i was in it came out really nice. 3 base coats and 2 top coats,next time im doing 5 base with a stenciled black logo before i add 3 top coats.

any word on thos flanges yet?

anyways did u use the metal cast paint from duplicolor? thats what i used and must say for the hurry i was in it came out really nice. 3 base coats and 2 top coats,next time im doing 5 base with a stenciled black logo before i add 3 top coats.

any word on thos flanges yet?

#82

i dont know if thosw will work with the 3rdgen ecms(idle air control motor)

anyways did u use the metal cast paint from duplicolor? thats what i used and must say for the hurry i was in it came out really nice. 3 base coats and 2 top coats,next time im doing 5 base with a stenciled black logo before i add 3 top coats.

any word on thos flanges yet?

anyways did u use the metal cast paint from duplicolor? thats what i used and must say for the hurry i was in it came out really nice. 3 base coats and 2 top coats,next time im doing 5 base with a stenciled black logo before i add 3 top coats.

any word on thos flanges yet?

The programs are done and a test cut was made (w/o the radius yet) to make sure they were a perfect match for the flange. They are PERFECT even though he had problems trying to measure a flimsy gasket, lmao. They should be done soon, he got set back a little bit when his boss' son threw away my downpipe flange that only needed to be counterbored when the scrap guy came to the shop while my friend was at lunch ;(. The boss' son felt so bad that he is writing a CNC program so the flanges will be available soon (the origional was being hand cut). It's going to be 1/2" steel with all the holes bored into it, then the exhaust exit is going to get a counter bore slightly larger than the down pipe to make it easy to weld to with my little machine.

I'll start a new thread for the turbo inlet/downpipe flanges that will be available in mild or stainless steel (various grades also).

#83

Junior Member

Join Date: Jan 2007

Location: Ocala, Florida

Posts: 35

Likes: 0

Received 0 Likes

on

0 Posts

Car: 1989 Pontiac Trans Am GTA

Engine: L98 TPI 5.7L

Transmission: Stock ... For now

Axle/Gears: Borg-Warner 9-Bolt

Spider Intake

I was talking to my fabricator about redoing my upper intake plenum and he suggested an smooth flow spider intake similar to the TPI 350. Would that work as good if not better than your box style plenum and if so about what diameter piping should I use to the ports on the lower plenum and how high should it be?

#86

Junior Member

Join Date: Oct 2006

Location: MI, in ohio for college

Posts: 82

Likes: 0

Received 0 Likes

on

0 Posts

Car: 91 camaro T-Tops

Engine: L03

Transmission: Borg T5

Axle/Gears: 3.23

I was talking to my fabricator about redoing my upper intake plenum and he suggested an smooth flow spider intake similar to the TPI 350. Would that work as good if not better than your box style plenum and if so about what diameter piping should I use to the ports on the lower plenum and how high should it be?

as far as what i've looked into it, the reason a long runner runs low rpm range is the length of the runner runs "dry" between intake valve openings. the shorter has less of a "reservior" so it won't fill the cyl as well b/c there's less readily avail air. ... long discussion kinda the same theory as columning effect of exhaust.

#87

I was talking to my fabricator about redoing my upper intake plenum and he suggested an smooth flow spider intake similar to the TPI 350. Would that work as good if not better than your box style plenum and if so about what diameter piping should I use to the ports on the lower plenum and how high should it be?

Here you go. They're almost $1000, want one?

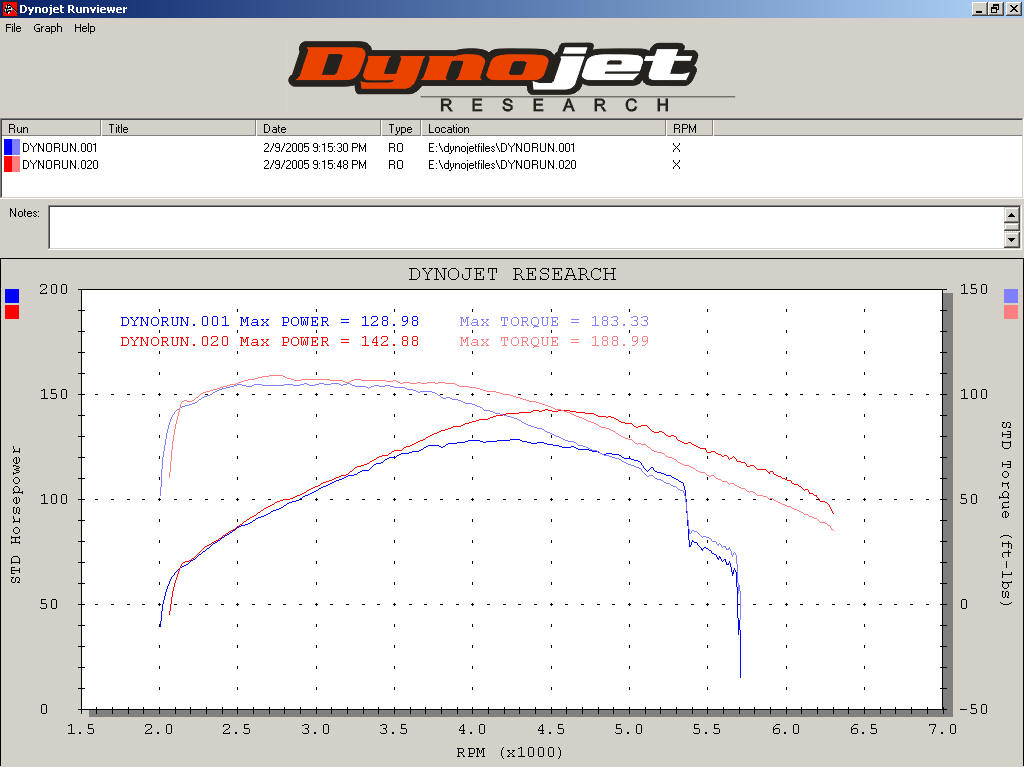

EDIT : I can't see spending almost a grand for less than 20hp. Although it would probably work better on a turbo motor. Here's the dyno for it...

#88

Junior Member

Join Date: Oct 2006

Location: MI, in ohio for college

Posts: 82

Likes: 0

Received 0 Likes

on

0 Posts

Car: 91 camaro T-Tops

Engine: L03

Transmission: Borg T5

Axle/Gears: 3.23

Somebody should probably start a sticky for intake runner design in the engine/fabrication portion. It's a interesting discussion, I've read for a number of hours on just that topic alone. I don't have sources to cite for it right now, but I remember Engine Masters magazine had some really in depth articles on how it works.

#89

Senior Member

Join Date: Jul 2003

Location: Bellingham, WA

Posts: 692

Likes: 0

Received 0 Likes

on

0 Posts

Car: 1989 RS

Engine: 3.1L + .060" overbore

Transmission: 700R4

Axle/Gears: 4.11, Auburn LSD

I know I keep thinking of it, but why not put a TBI setup on your car? They have short runners, decent plenum volume, and you can put the 4.3 throttle assembly on it. If you're really going for HP, this may be a better idea. Get rid of those long a$$ TPI runners altogether.

I just looked it up, the TBI 2.8 made 150ft.lbs. of torque, just like the treolo intake, and I bet it would make a butt load more HP if cleaned up.

I just looked it up, the TBI 2.8 made 150ft.lbs. of torque, just like the treolo intake, and I bet it would make a butt load more HP if cleaned up.

Last edited by Blue1989RS; 02-07-2007 at 10:51 AM.

#94

I know some of you guys are PM-ing Dave about when the manifolds are going to be ready, and I'll have to say it's my fault they aren't into production yet. The machinist has cut one flange only to realize that the bolt holes were not symmetrical, although the gaskets are a perfect match (he also wasn't happy with the 1/8" radius on the ports and re-wrote the program for a 3/16" radius) He promised them to me on Monday and I'll mail them to Dave ASAP. Sorry for the delay, but not only are the flanges going to be easier to make from here on out - they are going to be much better than a hand cut radius.

#99

Supreme Member

Thread Starter

iTrader: (3)

Join Date: Dec 2005

Location: Sayreville NJ

Posts: 2,472

Likes: 0

Received 0 Likes

on

0 Posts

there is one thing i forgot to mention about these,they will not work with a 2.8 throttle body due to the way the iac motor hooks up.these must be used with a 3.1 tb

they deff look better then my hand cut ones

they deff look better then my hand cut ones