Connecting Rod End Play

#1

Connecting Rod End Play

I'm rebuilding my stock 350. I have machine shop clean and bore it .10over with new rings. I also had every single rod checked out. One turned out to be bad so i replaced it with a reman he had at the shop. Its rod 3 now.

The engine has roller lifters, its center bolt, one piece rear main seal

The engine rebuild is just a stock rebuild. No cam, no heads, nothing just stock.

For connecting rod endplay Haynes manual says .014 max and Chiltons says .017.

Here are my measurements:

journal 7,8; .016

journal 5,6; .013

journal 3,4; .017

journal 1,2; .020

So my question is... what could be cause of this? and what can i do to resolve? or will it be fine how it is up to 5500rpm redline?

The engine has roller lifters, its center bolt, one piece rear main seal

The engine rebuild is just a stock rebuild. No cam, no heads, nothing just stock.

For connecting rod endplay Haynes manual says .014 max and Chiltons says .017.

Here are my measurements:

journal 7,8; .016

journal 5,6; .013

journal 3,4; .017

journal 1,2; .020

So my question is... what could be cause of this? and what can i do to resolve? or will it be fine how it is up to 5500rpm redline?

Last edited by wrath112; 12-21-2011 at 04:18 PM. Reason: Measurements Entered Incorrectly

#3

#4

Supreme Member

iTrader: (1)

Join Date: Sep 2005

Posts: 26,494

Received 1,855 Likes

on

1,414 Posts

Car: Yes

Engine: Usually

Transmission: Sometimes

Axle/Gears: Behind me somewhere

Re: Connecting Rod End Play

.013" is a bit on the tight side, but all are reasonable. I like to see about .015", give or take.

It's not critical at all. What happens is, the entire rod (both ends) slides from front to rear along the crank; as long as the pins don't hammer out the Spirolox (if you have to ask what those are, you don't have them) they're OK.

Wear and machining cause it. Completely normal for old parts.

It's not critical at all. What happens is, the entire rod (both ends) slides from front to rear along the crank; as long as the pins don't hammer out the Spirolox (if you have to ask what those are, you don't have them) they're OK.

Wear and machining cause it. Completely normal for old parts.

#5

Senior Member

Join Date: May 2002

Location: loxahatchee fla

Posts: 564

Likes: 0

Received 0 Likes

on

0 Posts

Re: Connecting Rod End Play

btw , if you have the correct micrometers and feeler gauges you might try piston and rod #2 with #6 OR #5 and #1 as it might result in a more consistent rod side clearance

journal 7,8; .016

journal 5,6; .013

journal 3,4; .017

journal 1,2; .020

journal 7,8; .016

journal 5,6; .013

journal 3,4; .017

journal 1,2; .020

#6

Re: Connecting Rod End Play

so grumpyvette, what exactly does that mean??...

picture mean that if i have a connecting rod and piston upside does would cause to much endplay??..

this is my first engine rebuild by my self. I have done it before, last year, but had alot of help and missed out on some of the assembly. It was more along the lines of go get this and that oh btw your gonna need to buy this. One of those kinda gigs.

SO

my pistons have 4 valve reliefs though, and they are the same size. So i really do not know how to tell if they are upside down and backwards. However though, i noticed while putting the connecting rods in they wouldnt go in one way but if you turned it around they would go right in like they were supposed to.

OR basically are you suggesting to install connecting rod 6 in the number 2 slot or the number 1 slot.

picture mean that if i have a connecting rod and piston upside does would cause to much endplay??..

this is my first engine rebuild by my self. I have done it before, last year, but had alot of help and missed out on some of the assembly. It was more along the lines of go get this and that oh btw your gonna need to buy this. One of those kinda gigs.

SO

my pistons have 4 valve reliefs though, and they are the same size. So i really do not know how to tell if they are upside down and backwards. However though, i noticed while putting the connecting rods in they wouldnt go in one way but if you turned it around they would go right in like they were supposed to.

OR basically are you suggesting to install connecting rod 6 in the number 2 slot or the number 1 slot.

Last edited by wrath112; 12-21-2011 at 07:25 PM.

#7

Supreme Member

iTrader: (1)

Join Date: Sep 2005

Posts: 26,494

Received 1,855 Likes

on

1,414 Posts

Car: Yes

Engine: Usually

Transmission: Sometimes

Axle/Gears: Behind me somewhere

Re: Connecting Rod End Play

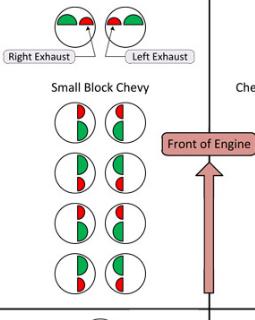

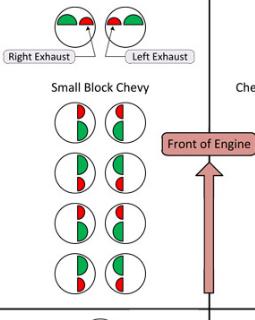

Look at the pic.

There is a definite "cam" side and "oil pan" side to a rod; and a definite "front" and "rear" to a piston.

Therefore (assuming your parts are assembled correctly...) you have 4 variants of piston/rod combo: #1 & #5, #3 & #7, #2 & #6, and #4 & #8. Without re-hanging the rods on the pistons the other way, you can swap within those pairs, if the balance isn't too terribly bad, which if they're a FACTORY SET of rods (as opposed to just 8 random rods from who knows where), it won't be. Reason for that being, the factory doesn't "balance" a motor the same way we do out here in hobbyist or service world. Rather, they keep an n-dimensional array of bins, where they sort rods as they come off the production line by big end weight, small end weight, total weight, and whatever else; they know exactly what measurements a crank will require to match to each bin; and when they get 8 rods in a bin, they machine a crank to match, and put the motor together.

Ever drive a new car that had an imbalance problem? From ANY mfr? Me either. No doubt it happens, but the process is pretty much bulletproof in the vast majority of cases.

So a FACTORY SET of rods is consistent in a way that is very difficult to duplicate outside the factory, even though their methods are somewhat ... crude. But the benefit of their method is, the rods in any given motor are all pretty much THE SAME within whatever their tolerances are, meaning, you can get away with swapping em around WITHIN THEIR ORIGINAL SET like that.

8 random rods from 8 random motors won't necessarily be like that. Aftermarket ones won't be that way unless somebody has meticulously made them like that. But a FACTORY SET is interchangeable.

There is a definite "cam" side and "oil pan" side to a rod; and a definite "front" and "rear" to a piston.

Therefore (assuming your parts are assembled correctly...) you have 4 variants of piston/rod combo: #1 & #5, #3 & #7, #2 & #6, and #4 & #8. Without re-hanging the rods on the pistons the other way, you can swap within those pairs, if the balance isn't too terribly bad, which if they're a FACTORY SET of rods (as opposed to just 8 random rods from who knows where), it won't be. Reason for that being, the factory doesn't "balance" a motor the same way we do out here in hobbyist or service world. Rather, they keep an n-dimensional array of bins, where they sort rods as they come off the production line by big end weight, small end weight, total weight, and whatever else; they know exactly what measurements a crank will require to match to each bin; and when they get 8 rods in a bin, they machine a crank to match, and put the motor together.

Ever drive a new car that had an imbalance problem? From ANY mfr? Me either. No doubt it happens, but the process is pretty much bulletproof in the vast majority of cases.

So a FACTORY SET of rods is consistent in a way that is very difficult to duplicate outside the factory, even though their methods are somewhat ... crude. But the benefit of their method is, the rods in any given motor are all pretty much THE SAME within whatever their tolerances are, meaning, you can get away with swapping em around WITHIN THEIR ORIGINAL SET like that.

8 random rods from 8 random motors won't necessarily be like that. Aftermarket ones won't be that way unless somebody has meticulously made them like that. But a FACTORY SET is interchangeable.

Trending Topics

#8

Supreme Member

Re: Connecting Rod End Play

.020 is a bit high but not objectionable on a stock rebuild. The lid is .025" according to Chevy.

Before you freak out about the pistons please understand that the ROD orientation comes first. ALL bearing tab reliefs have to point towards the pan rail of the bank that rod is installed in. If that means that some of your pistons are not in proper orientation when you do that you have to get the pistons flipped on the rods. You do NOT flip the rod on it's journal to fix a piston orientation problem.

Most pistons (and almost all stock ones) have simple "front-to-back" orientation where there is a dot that must point towards the front of the engine when it is installed. That means half the pistons get mounted one way on the rods (the "even" bank), the other half get mounted the opposite way (the "odd" bank).

All of this assumes you marked the rods and put them back in the same hole they came out of with the exception of #3 which got replaced.

Before you freak out about the pistons please understand that the ROD orientation comes first. ALL bearing tab reliefs have to point towards the pan rail of the bank that rod is installed in. If that means that some of your pistons are not in proper orientation when you do that you have to get the pistons flipped on the rods. You do NOT flip the rod on it's journal to fix a piston orientation problem.

Most pistons (and almost all stock ones) have simple "front-to-back" orientation where there is a dot that must point towards the front of the engine when it is installed. That means half the pistons get mounted one way on the rods (the "even" bank), the other half get mounted the opposite way (the "odd" bank).

All of this assumes you marked the rods and put them back in the same hole they came out of with the exception of #3 which got replaced.

Last edited by Damon; 12-21-2011 at 08:39 PM.

#9

Re: Connecting Rod End Play

yeah while taking it apart, i punched the main caps and block w/ a,b,c, etc, and the rods and rod caps 1,2,3etc

the only thing that is different about the individual pistons that i can tell is the there is a notch out of ONE side. Like on the right side, and the notch is opposite on the other side. They are all the same way. I am pretty certain that everything is installed correctly.

But i will make sure before i put the heads back on, etc. lol

Thanks for the help.

I might trying swapping 1 with 5, i will let you guys know how everything turns out.

the only thing that is different about the individual pistons that i can tell is the there is a notch out of ONE side. Like on the right side, and the notch is opposite on the other side. They are all the same way. I am pretty certain that everything is installed correctly.

But i will make sure before i put the heads back on, etc. lol

Thanks for the help.

I might trying swapping 1 with 5, i will let you guys know how everything turns out.

#10

Supreme Member

Re: Connecting Rod End Play

All the notches in the pistons need to point towards the front of the engine. That's the "front-to-back" piston orientation I was talking about. Sounds like you got it right.

Thread

Thread Starter

Forum

Replies

Last Post

ambainb

Camaros for Sale

11

04-25-2016 09:21 PM