Adjusting IAC valve, doesn't work

#1

Supreme Member

Thread Starter

Join Date: Aug 2001

Location: Costal Alabama

Posts: 2,136

Likes: 0

Received 1 Like

on

1 Post

Car: 1989 Iroc-Z

Engine: 350, ZZ4 equivalent

Transmission: Pro-Built Road Race 700R4

Axle/Gears: 3.23 Dana 44

Adjusting IAC valve, doesn't work

I read the tech article on how to adjust the IAC valve. It says to adjust the idle with the IAC valve disconnected. It says to adjust the idle pin so the car idles at 450 RPM's but I can't get my car to go that low without stalling out. Anyone have the same problem when trying to adjust the valve?

------------------

1989 Iroc-Z 5.7 350, Blue, T-Tops

Lightly Moded:

Edelbrock Headers, Rebuilt B&M 700R-4 Tranny, Higher Stall Torque Converter, Airfoil, 3.4 w\posi, K&N's, Ported Plenum

-- Blue LED Bakelite Dash & Climate Control

"Just some 17 Year old spending every dollar I make on my car."

------------------

1989 Iroc-Z 5.7 350, Blue, T-Tops

Lightly Moded:

Edelbrock Headers, Rebuilt B&M 700R-4 Tranny, Higher Stall Torque Converter, Airfoil, 3.4 w\posi, K&N's, Ported Plenum

-- Blue LED Bakelite Dash & Climate Control

"Just some 17 Year old spending every dollar I make on my car."

#2

Does the article really say 450 rpm ?? I wouldn't go that low. The general idea is to set the idle to what you want to car to idle after you plug in the IAC while staying close to the factory preset of 650 RPM. I would try to set it at 650RPM and go from there. If you can't idle at 650 then you have other problems...

------------------

1991 Z28 5.7 TPI

ZZ4 heads, ZZ4 cam, Harland Sharp roller rockers, Accel base, SLP siamesed runners, 52MM SLP Throttle Body, Hooker Headers, Flowmaster catback, MSD6A ignition, Home made ramair system, 2500 stall, bullet proof 700R4, aluminum driveshaft...

Soon to be installed. WC T5 !

------------------

1991 Z28 5.7 TPI

ZZ4 heads, ZZ4 cam, Harland Sharp roller rockers, Accel base, SLP siamesed runners, 52MM SLP Throttle Body, Hooker Headers, Flowmaster catback, MSD6A ignition, Home made ramair system, 2500 stall, bullet proof 700R4, aluminum driveshaft...

Soon to be installed. WC T5 !

#3

Senior Member

iTrader: (1)

Join Date: Nov 1999

Location: Hayward, CA

Posts: 893

Likes: 0

Received 0 Likes

on

0 Posts

Car: 91 camaro

Engine: 383

Transmission: T56

Yeah, I had that problem too. I just adjusted it as low as I could get it without stalling. You wouldn't want to adjust the screw to the rpm you want it to idle at; you should adjust it much lower. The IAC does the work to bring the rpm back up to where it should be.

#6

<font face="Verdana, Arial" size="2">Originally posted by crucial:

Does the article really say 450 rpm ?? I wouldn't go that low. The general idea is to set the idle to what you want to car to idle after you plug in the IAC while staying close to the factory preset of 650 RPM. I would try to set it at 650RPM and go from there. If you can't idle at 650 then you have other problems...

</font>

Does the article really say 450 rpm ?? I wouldn't go that low. The general idea is to set the idle to what you want to car to idle after you plug in the IAC while staying close to the factory preset of 650 RPM. I would try to set it at 650RPM and go from there. If you can't idle at 650 then you have other problems...

</font>

That is the correct setting for the throttle minimum air position, not the final idle speed. The theory of operation is to set the hard stop for the throttle at a point of reference for the engine so that the ECM can control the IAC (and thus, engine RPM) effectively. Setting the minimum position above that range can cause the IAC to wander in the lower opening ranges and overspeed the engine on cold starts. The IAC will always be operating well under the 128 base count range that is is designed to use, and will have poor idle control. If you try to adjust the base idle speed above the design RPM by any other means than reprogramming the PROM, you're not fooling the ECM, only yourself.

The Tech Article may be a little confusing, so here is a different approach:

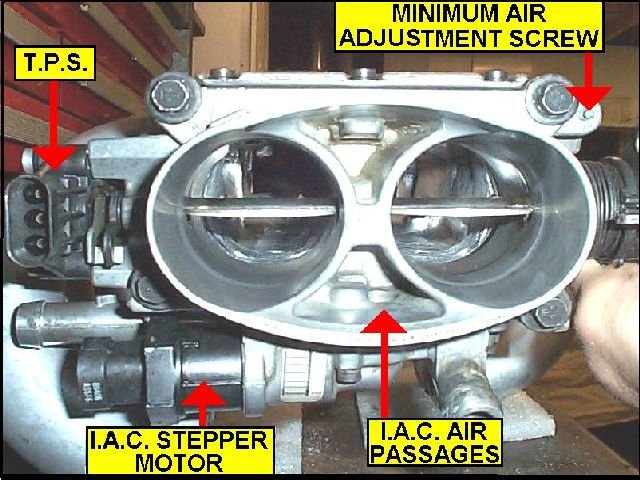

Throttle Minimum Air Position

Tools needed:

1. Torx driver # T-20

2. Paper Clip

3. Small Punch

4. Tachometer

GENERAL NOTE: The engine should be at normal operating temperature before performing any adjustments. Never rely on the dash mounted instruments for diagnostics and adjustments. The oil pressure and temperature gauges and the voltmeter and tachometer just aren't calibrated accurately enough for diagnosis, but are a relative indication for monitoring the vehicle while driving.

For this adjustment, the transmission will be in DRIVE while you're under the hood. You will need to securely set the parking brake and block the drive wheels. It would also be a good idea to have an assistant hold the service brake while you perform the adjustments.

In order to successfully complete the adjustment, the IAC air passages and pintle need to be clean. The throttle plates and bores need to be clean as well. If this is not the case, you'll need to remove the air cleaner from TBI engines or the intake air bellows from TPI engines to gain access to the area to be cleaned. A spray-type carburetor cleaner works well for this. Cleaning the IAC passages on a TPI/MAF engine will set a DTC, but we'll be clearing that later. With the engine idling, direct the spray cleaner in to the IAC air passages and around the throttle plates. Shut off the engine and continue cleaning the throttle plates by opening the throttle manually. Once everything is satisfactorily cleaned, replace the air bellows on TPI engines. Many times, this alone can solve IAC/idle speed problems.

If this doesn't solve the problem, you may need to remove and clean the IAC stepper motor. If the IAC appears to be clean and functioning properly, continue with the adjustment procedure.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Idle Air Control Cleaning

You can remove the IAC and service it. Remove the electrical connector from the IAC. Unscrew the IAC unit from the throttle body.

DON'T do what I did the first time! I removed the IAC, plugged it back in to watch operation, then turned on the ignition. The IAC stepped the pintle out to full extended position until the spring took over and launched the pintle across the garage. A while later, after moving a couple of other cars and several pieces of equipment, I found all the parts I needed to reassemble the unit.

You can gently rock the pintle back and forth and allow the spring to extend it until it comes apart in your hands. Clean everything with lint-free cloths and a mild solvent. Harsh solvents can affect the insulation of the stepper motor coils. It's generally the dirt and buildup on this worm shaft that causes sluggish IAC operation.

When the worm gear on the pintle shaft is clean and dry, apply one drop of clean light oil to the shaft and work the pintle back into the rack gears of the motor by the same rocking motion. It takes a while to get the pintle back into the worm gears, but you'll get it. It is important to get the pintle fully retracted into the housing so that the pintle is not forced against the gears when reinstalling the IAC unit in the throttle body.

While the IAC is out, clean the air passages in the throttle body. The oriface in the TB where the IAC resides is the seat that the IAC valve closes against, and it can accumulate a lot of carbon, dirt, and debris. The easy way to do this is with carburetor cleaner and a small stiff brush. Another "DON'T" - don't use your sister's toothbrush.

When everything is clean and dry, replace the gasket if it is damaged, apply a little anti-seize to the threads, and torque the IAC to the proper specs. (13 ft/lb for '85-'89 , 30 in/lb for 1990-on.) Proceed with setting the TPS and minimum air position.

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Cut and form a paper clip into a "U" shape. Insert the clip ends into the ALDL in the 'A' and 'B' sockets. Turn on the ignition, but don't start the engine. This will force the ECM into its diagnostic mode. Wait 30 seconds to allow the IAC pintle to fully extend. Under the hood, remove the electrical connector from the IAC, then turn off the ignition and remove the paper clip jumper from the ALDL. With the IAC pintle fully extended (closed) all idle air will be controlled by the position of the throttle plates. Some manuals indicate that the EST bypass connector should be disconnected for this procedure, while some make no mention of it. While timing is a factor in idle speed, the EST should only operate as a function of engine RPM, temperature, and detonation sensor inputs. To remove all doubt, disconnect the EST bypass connector is your car is so equipped. Some TBI and V-6 engines do not have this bypass connector, and therefore must be set with no regard to the EST system. The EST can be bypassed on some cars by grounding the diagnostic terminal at the ALDL and continuing with the procedure, but the fuel mixture will be skewed to the rich side, affecting idle speed as well. In any event, the minimum air position idle speed range is wide enough to allow for some variations. As always, it is best to consult your service manual for the exact procedure for your system.

Locate the Torx screw on the left side of the throttle body. It may be equipped with a protective metal cap from the factory. This was intended to discourage adjustment. If the cap is present, use a small punch to knock it out. Once the screw is accessible, start the engine and place the transmission in DRIVE. Adjust the throttle stop to obtain 400 RPM with the transmission in "DRIVE" on an automatic transmission car, 450 in neutral on a manual transmission car, rotating the Torx screw clockwise to raise speed and counter-clockwise to lower speed. Once the idle RPM is set, place the transmission in PARK and turn off the engine.

Re-connect the electrical connector onto the IAC. Start engine. Idle speed should be governed by the ECM at approximately 600-650 rpm in "DRIVE" (for unmodified cars). Idle speed in NEUTRAL or PARK is less significant, and will be higher.

Throttle Position Sensor (TPS)

Tools needed:

1. Digital Volt-Ohm-Meter (VOM)

2. Breakout jumper wires or probes (make your own)

3. AutoXray, Diacom, or similar scanner will replace the VOM and jumper wires.

Turn on ignition, but don't start the engine.

With a diagnostic scanner: plug in the scanner and read the TPS voltage. It should be 0.54Volts +/- 0.07 VDC.

Connect the VOM to the TPS electrical connector terminals ‘A' and ‘B'.

With a breakout jumper: Disconnect the electrical connector from the TPS. Install the breakout in-line, between the TPS and wiring harness connector. Connect the meter probes to terminals 'A' and 'B' on the connector. (‘B' is the positive connection, ‘A' the signal ground, or negative.)

With probes: If you have very slender probes on your VOM, you can back-probe the TPS connector while it is attached to the TPS. If you have made probes of large dressmakers pins or a similar item, you can back-probe the connector as well. Connect the meter probes to terminals 'A' and 'B' on the connector.

Turn on the ignition to read the TPS output voltage at the idle position. The reading should be 0.54VDC +/- 0.07VDC. The ideal is the center of the range, 0.54VDC for a stock engine. To adjust the output voltage, loosen the two Torx screws holding the TPS to the throttle body, and slightly rotate the TPS up or down, reading the voltage until it comes into specification. Tighten screws. Using the throttle lever, rotate the throttle to WOT (wide open throttle). The TPS voltage should be over 4.0 volts. Close the throttle again, and then slowly open it to WOT, observing the voltage reading. It should increase progressively and in a linear fashion. If it sticks or jumps or falls off at all while doing this check, the TPS sensor may be failing and could be a cause of stumbling and driveability problems.

After achieving the desired setting, turn off the ignition switch. Remove all jumpers or the scanner and reconnect the TPS connector as required.

Reinitializing the ECM

If you set a DTC during the procedure, the SES light should be illuminated on the dash. This ECM retains DTC data for the previous 50 engine starts, so the codes will eventually be cleared. If you want more immediate results, after shutting down the engine disconnect the negative battery terminal for five minutes. This will clear the ECM of all diagnostic trouble codes. Clearing the ECM also clears any data learned about your engine, and clears the radio presets. If you have a Delco-Loc or Theft Loc II radio, make sure you follow the procedure to unlock the radio protection before disconnecting the battery. This five minutes is also just about long enough to clean both battery cables. Reconnect the battery. When you first start the engine after clearing the ECM, the engine will operate with base parameters programmed into the ECM PROM. These parameters may not be optimum for your engine, but the ECM will enter a Block Learn Mode soon after the engine is warm and enters Closed Loop Mode. The ECM will write new data tables specific to your engine and will eventually rely on those tables instead of the base tables of the factory program. You can expedite this process by driving the car for 20 minutes under varying conditions to allow the ECM to initialize. Or you can wait and drive the car normally at your convenience. The BLM tables are constantly being updated as sensor input ranges change, but the greatest change will occur within the first twenty minutes of Closed Loop operation.

------------------

Later,

Vader

------------------

If you want to beat the World, it might reach up and pull you down...

Adobe Acrobat Reader

Last edited by Vader; 08-21-2012 at 11:01 PM. Reason: Updated image links

The following users liked this post:

1991LE (07-15-2019)

#7

I doubt an engine will idle very well THAT low. If you actually knew how the ECM controls the IAC motor you wouldn't be saying that Vader. I'm not gonna go into detail, but the IAC cross counts should be very close to 0 which means the ECM should NOT have to have to correct the idle by allowing more air to come in to raise the idle speed another 200-300 rpm.

------------------

1991 Z28 5.7 TPI

ZZ4 heads, ZZ4 cam, Harland Sharp roller rockers, Accel base, SLP siamesed runners, 52MM SLP Throttle Body, Hooker Headers, Flowmaster catback, MSD6A ignition, Home made ramair system, 2500 stall, bullet proof 700R4, aluminum driveshaft...

Soon to be installed. WC T5 !

------------------

1991 Z28 5.7 TPI

ZZ4 heads, ZZ4 cam, Harland Sharp roller rockers, Accel base, SLP siamesed runners, 52MM SLP Throttle Body, Hooker Headers, Flowmaster catback, MSD6A ignition, Home made ramair system, 2500 stall, bullet proof 700R4, aluminum driveshaft...

Soon to be installed. WC T5 !

Trending Topics

#8

You want the idle with the IAC disconnected to match the idle with it connected, so the IAC doesnt have to open as far to maintain the correct idle. The less work the IAC has to do, the better stall protection you have.

------------------

1991 Camaro Z28

5.7L 5-Speed (originally 305)

317 RWHP, 418 RWTQ

13.23 @ 107.62 MPH

Southern California

Member: SoCal 3rd Gen F-Bodies

Member: SoCal F-Bodies

-=ICON Motorsports=-

------------------

1991 Camaro Z28

5.7L 5-Speed (originally 305)

317 RWHP, 418 RWTQ

13.23 @ 107.62 MPH

Southern California

Member: SoCal 3rd Gen F-Bodies

Member: SoCal F-Bodies

-=ICON Motorsports=-

#10

O.K., but I'm only repeating the factory procedure for correct minimum air position adjustment.

If you hack a binary file from a TPI PROM, you might find that the target RPM actually has to be LOWER than 650 RPM in DRIVE when the coolant temperature rises above 200°F (550 RPM, actually). I think it would be difficult for the ECM to do that if the minimum air position is set that high:

; RPM/12.5 Deg c COOL

LC637 FCB 84 ; 1050 -40

LC638 FCB 84 ; 1050 -28

LC639 FCB 84 ; 1050 -16

LC63A FCB 84 ; 1050 -4

LC63B FCB 84 ; 1050 8

LC63C FCB 76 ; 950 20

LC63D FCB 72 ; 900 32

LC63E FCB 60 ; 750 44

LC63F FCB 48 ; 600 56

LC640 FCB 48 ; 600 68

LC641 FCB 44 ; 550 80

LC642 FCB 44 ; 550 92

LC643 FCB 44 ; 550 104

LC644 FCB 44 ; 550 116

LC645 FCB 44 ; 550 128

LC646 FCB 44 ; 550 140

LC647 FCB 44 ; 550 152

And my '86 TPI has a PROMMED target for idle couts at 128, not zero:

LC62E: FCB 128 ; RPM 12.5 Msec Filter Coef, (0.5)

; CALIB = Arg * 256

LC62F: FCB 144 ; Idle Spd Start up park posit.

; CALIB = Arg

LC630: FCB 32 ; Steps Added to Warm Park posit if

; hot restart spark retard is active.

LC631: FCB 10 ; Steps Added to Warm Park down if

; A/C on during start up.

LC632: FCB 5 ; Add Steps for Fan Anticipate

; CALIB = Arg/2

LC633: FCB 5 ;Add Offset for Cold Engine

;when cold spark has expired

;

; Cmd Speed Definitions

;

LC634: FCB 4 ; IAC offset added for pk/neut

; CALIB = Arg/12.5, (50 RPM)

LC635: FCB 160 ; Idle Speed Strt up Dly Time

; CALIB = Arg/6.25, (1000 Sec)

LC636: FCB 0 ; IAC Offset Cmd Spd Added

; CALIB = Num/12.5, (RPM)

The only correct way to adjust the RPM beyond the factory settings is to change the multipliers or base parameters in the PROM bin.

As for other engines, even both of my LT1s operate the IAC at over 30% and varying at hot idle. Most of the OBD-II cars I've scanned do the same. I guess I presuned the factory manual was correct.

Just my 2¢

------------------

Later,

Vader

------------------

If you want to beat the World, it might reach up and pull you down...

Adobe Acrobat Reader

If you hack a binary file from a TPI PROM, you might find that the target RPM actually has to be LOWER than 650 RPM in DRIVE when the coolant temperature rises above 200°F (550 RPM, actually). I think it would be difficult for the ECM to do that if the minimum air position is set that high:

; RPM/12.5 Deg c COOL

LC637 FCB 84 ; 1050 -40

LC638 FCB 84 ; 1050 -28

LC639 FCB 84 ; 1050 -16

LC63A FCB 84 ; 1050 -4

LC63B FCB 84 ; 1050 8

LC63C FCB 76 ; 950 20

LC63D FCB 72 ; 900 32

LC63E FCB 60 ; 750 44

LC63F FCB 48 ; 600 56

LC640 FCB 48 ; 600 68

LC641 FCB 44 ; 550 80

LC642 FCB 44 ; 550 92

LC643 FCB 44 ; 550 104

LC644 FCB 44 ; 550 116

LC645 FCB 44 ; 550 128

LC646 FCB 44 ; 550 140

LC647 FCB 44 ; 550 152

And my '86 TPI has a PROMMED target for idle couts at 128, not zero:

LC62E: FCB 128 ; RPM 12.5 Msec Filter Coef, (0.5)

; CALIB = Arg * 256

LC62F: FCB 144 ; Idle Spd Start up park posit.

; CALIB = Arg

LC630: FCB 32 ; Steps Added to Warm Park posit if

; hot restart spark retard is active.

LC631: FCB 10 ; Steps Added to Warm Park down if

; A/C on during start up.

LC632: FCB 5 ; Add Steps for Fan Anticipate

; CALIB = Arg/2

LC633: FCB 5 ;Add Offset for Cold Engine

;when cold spark has expired

;

; Cmd Speed Definitions

;

LC634: FCB 4 ; IAC offset added for pk/neut

; CALIB = Arg/12.5, (50 RPM)

LC635: FCB 160 ; Idle Speed Strt up Dly Time

; CALIB = Arg/6.25, (1000 Sec)

LC636: FCB 0 ; IAC Offset Cmd Spd Added

; CALIB = Num/12.5, (RPM)

The only correct way to adjust the RPM beyond the factory settings is to change the multipliers or base parameters in the PROM bin.

As for other engines, even both of my LT1s operate the IAC at over 30% and varying at hot idle. Most of the OBD-II cars I've scanned do the same. I guess I presuned the factory manual was correct.

Just my 2¢

------------------

Later,

Vader

------------------

If you want to beat the World, it might reach up and pull you down...

Adobe Acrobat Reader

#11

Member

Join Date: Jun 2002

Location: Ebony, VA

Posts: 159

Likes: 0

Received 0 Likes

on

0 Posts

Car: 1987 IROC-Z; 2012 Ford Raptor

Engine: Modified 350

Transmission: 700R4

IAC and TPS Questions

OK, adjust min air IAC and then do TPS. How about somebody taking and posting a photo of actually taking the voltage measurement. That way, us novices can see the jumper and the connections to the voltmeter. Maybe some photos of the IAC removal and cleaning would help too. The IAC needs a 1 1/4 inch socket or wrench to remove it. Actually, my socket wall is too thick and will not fit between the Throttle body and IAC.

Also, I read that the carb cleaners are not good for use on the TPI assembly. There is a TPI, Throttle body cleaner with different ingredients. Try that instead.

Finally, when can the timing be set? Is it prior to or after the other adjustments are made?

Scott

Also, I read that the carb cleaners are not good for use on the TPI assembly. There is a TPI, Throttle body cleaner with different ingredients. Try that instead.

Finally, when can the timing be set? Is it prior to or after the other adjustments are made?

Scott

#12

Senior Member

Join Date: May 2002

Location: Santiago, CHILE

Posts: 507

Likes: 0

Received 5 Likes

on

3 Posts

Car: 1986 Pontiac Firebird Trans Am

Engine: 305 Tuned Port Injection

Transmission: The famous 700R4

Axle/Gears: No idea

O.K., but note that the famous 0.54 V for the TPS voltage is a "number impossible", because the raw data from the ECM will be any number between 0 & 255 / 51, thus the most aprox. number into the raw data is 28, and 28/51 = 0.55volts or 27/51 = 0.53volts. I don't know if all datastraems are the same, but it's my experience.

Denis V.

Denis V.

#13

Supreme Member

If the adjustement doesn't seem to be working for you here's the usual reason why (this is a VERY important step, and very easy to miss if you haven't done this a few times):

Taken with copyright permission from Vader's extensive post. Just thought I'd highlight this some more. It's CRITICAL.

Cut and form a paper clip into a "U" shape. Insert the clip ends into the ALDL in the 'A' and 'B' sockets. Turn on the ignition, but don't start the engine. This will force the ECM into its diagnostic mode. Wait 30 seconds to allow the IAC pintle to fully extend. Under the hood, remove the electrical connector from the IAC, then turn off the ignition and remove the paper clip jumper from the ALDL. With the IAC pintle fully extended (closed) all idle air will be controlled by the position of the throttle plates.

#14

Member

Join Date: Jun 2008

Location: Belgium

Posts: 113

Likes: 0

Received 0 Likes

on

0 Posts

Car: 88 Camaro V6

Transmission: T5

Re: Adjusting IAC valve, doesn't work

Not only does ...

Idle speed should be governed by the ECM at approximately 600-650 rpm in "DRIVE" (for unmodified cars). Idle speed in NEUTRAL or PARK is less significant, and will be higher......

------------------

Later,

Vader

------------------

If you want to beat the World, it might reach up and pull you down...

Adobe Acrobat Reader

Idle speed should be governed by the ECM at approximately 600-650 rpm in "DRIVE" (for unmodified cars). Idle speed in NEUTRAL or PARK is less significant, and will be higher......

------------------

Later,

Vader

------------------

If you want to beat the World, it might reach up and pull you down...

Adobe Acrobat Reader

How much should the idle speed be with a manual transmission?

Mine is about 2300 cold, 1500 in between and 1000RPM at normal temperature. Is 1000 too much? I set the TPS to 0.55 VDC like the article said (thanks Vader). It was 0.42 VDC before but the warm idle is still 1000 RPM after resetting it.

Also I find it takes a long time to come to idle after quickly releasing the gaspedal at higher RPM. It doesn't react immedeately (hope i'm translating this in a way you can understand it).

Thread

Thread Starter

Forum

Replies

Last Post