Idle from 800 to 1250 after air box gut

#1

Supreme Member

Thread Starter

Join Date: Feb 2000

Location: Seattle, Washington

Posts: 1,170

Likes: 0

Received 0 Likes

on

0 Posts

Car: '87 IROC-Z/'82 RX7

Engine: SBC 355/1.1L Rotary

Transmission: T56/5 Speed

Axle/Gears: 4.33/3.93

Idle from 800 to 1250 after air box gut

'85 Z28 TPI 305

Gutted my air boxes, and took out 1 screen from my MAF. My idle went from 800 to 1250. When I kick it into drive, the rpm goes down to the normal Approx 600. When I put back in neutral or park, the rpm goes back up to 1100-1250. What's the deal? Will adjusting the IAC fix this? Thankies!

------------------

'85 Z28 305 TPI. Edlebrock Strut Tower Brace. IROC wheels. Fog Lights. Upcoming mods: Headers to tail pipe performance. Rear shocks. Panhard Rod. Sway Bars. MSD. New Intake.

Gutted my air boxes, and took out 1 screen from my MAF. My idle went from 800 to 1250. When I kick it into drive, the rpm goes down to the normal Approx 600. When I put back in neutral or park, the rpm goes back up to 1100-1250. What's the deal? Will adjusting the IAC fix this? Thankies!

------------------

'85 Z28 305 TPI. Edlebrock Strut Tower Brace. IROC wheels. Fog Lights. Upcoming mods: Headers to tail pipe performance. Rear shocks. Panhard Rod. Sway Bars. MSD. New Intake.

#3

Before you adjust anything, disconnect your battery for 20minutes.

Then see if the problem goes away.

------------------

91 Formula

305 TPI 5speed

1LE/G92/WS6

K&N, SLP airfoil, ported/polished plenum, March pulleys, TB coolant bypass,Crane AFPR(47psi),Crane Gold 1.6rrs,MSD coil,MSD6AL, Holley 9mm wires,Bosch O2sensor, SLP headers & catback,3:73s w/Auburn posi,160* t-stat,JET 195* fan switch, Macewen white face gauges, Autometer gauges, Zoom hi-performance clutch.

Street legal with stock throttle body, runners,intake manifold,cam, and heads.

Then see if the problem goes away.

------------------

91 Formula

305 TPI 5speed

1LE/G92/WS6

K&N, SLP airfoil, ported/polished plenum, March pulleys, TB coolant bypass,Crane AFPR(47psi),Crane Gold 1.6rrs,MSD coil,MSD6AL, Holley 9mm wires,Bosch O2sensor, SLP headers & catback,3:73s w/Auburn posi,160* t-stat,JET 195* fan switch, Macewen white face gauges, Autometer gauges, Zoom hi-performance clutch.

Street legal with stock throttle body, runners,intake manifold,cam, and heads.

#4

Supreme Member

Thread Starter

Join Date: Feb 2000

Location: Seattle, Washington

Posts: 1,170

Likes: 0

Received 0 Likes

on

0 Posts

Car: '87 IROC-Z/'82 RX7

Engine: SBC 355/1.1L Rotary

Transmission: T56/5 Speed

Axle/Gears: 4.33/3.93

Gah help! I tried setting my IAC, however.... When I start the engine with the IAC disconnected, it wont hold an idle. It's difficult to start without giving it some gas. I've tried turning the idle screw both ways, and I can't get it to idle right. What's going on? Oh yeah, then it throws me a code 34.

#5

Here we go again....

This is why MAF screens should be left alone until the engine is running at 6,500 RPM or you've punched it to over 365 cubes.

Will someone else please tell him? I hate to be the bearer of bad news all the time.

------------------

Later,

Vader

------------------

"I cannot take this any more... Saying everything I've said before..."

Adobe Acrobat Reader 4.0

[This message has been edited by Vader (edited January 11, 2001).]

This is why MAF screens should be left alone until the engine is running at 6,500 RPM or you've punched it to over 365 cubes.

Will someone else please tell him? I hate to be the bearer of bad news all the time.

------------------

Later,

Vader

------------------

"I cannot take this any more... Saying everything I've said before..."

Adobe Acrobat Reader 4.0

[This message has been edited by Vader (edited January 11, 2001).]

#6

Supreme Member

Thread Starter

Join Date: Feb 2000

Location: Seattle, Washington

Posts: 1,170

Likes: 0

Received 0 Likes

on

0 Posts

Car: '87 IROC-Z/'82 RX7

Engine: SBC 355/1.1L Rotary

Transmission: T56/5 Speed

Axle/Gears: 4.33/3.93

Well fine so I'll be idling a little high I'm going to get a new MAF when it's functioning. But how do I get my car here to idle with the IAC removed?

Trending Topics

#8

Red,

First, the MAF might still be functioning, but might not be reporting correctly to the ECM. If you substantially change the airflow pattern through the MAF body, the air flowing through the sampling tube may not be in correct proportion to the total air flowing through the housing. This has been the subject of many "Code 34" posts following a MAF modification. The intake air will follow the path of least resistance, and that might not be through the sampling tube if the screens are altered or the intake ducts are changed to alter the air flow path.

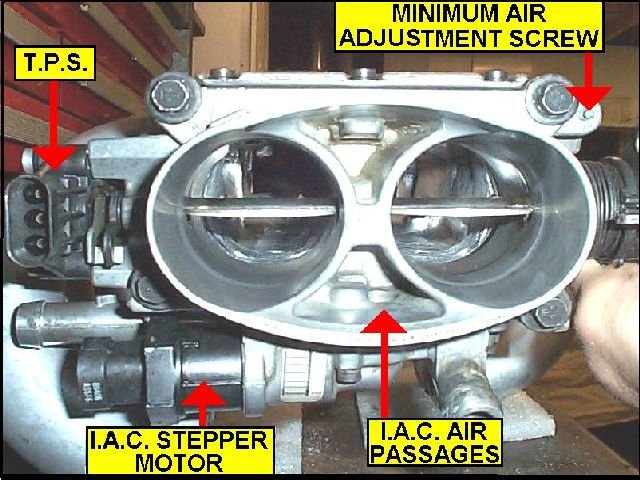

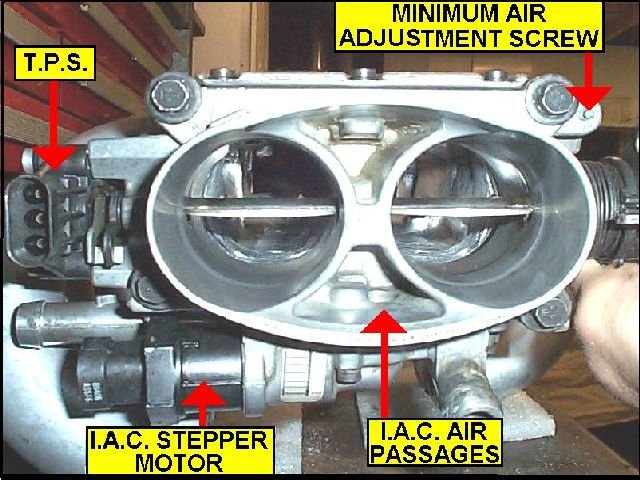

Second, the IAC should still be installed in the throttle body to set minimum air, but the electrical connector needs to be removed from the IAC after the stepper motor has been driven to the fully-closed position. Since you've moved the throttle stop screw and altered the intake air, you should set both the minimum idle air position and TPS setting. If you can't get the engine to idle long enough to do this, have an assistant crank the engine while you manipulate the throttle valve by hand under the hood. The engine needs to be fully warmed to get the correct adjustment, so you might be tweaking the throttle for a while until it will run by itself and is warm enough. The correct procedure is as follows:

Throttle Position Sensor (TPS)

Tools needed:

1. Digital Volt-Ohm-Meter (VOM)

2. Breakout jumper wires or probes (make your own)

3. AutoXray, Diacom, or similar scanner will replace the VOM and jumper wires.

Turn on ignition, but don't start the engine.

With a diagnostic scanner: plug in the scanner and read the TPS voltage. It should be 0.54Volts +/- 0.07 VDC.

Connect the VOM to the TPS electrical connector terminals ‘A' and ‘B'.

With a breakout jumper: Disconnect the electrical connector from the TPS. Install the breakout in-line, between the TPS and wiring harness connector. Connect the meter probes to terminals 'A' and 'B' on the connector. (‘B' is the positive connection, ‘A' the signal ground, or negative.)

With probes: If you have very slender probes on your VOM, you can back-probe the TPS connector while it is attached to the TPS. If you have made probes of large dressmakers pins or a similar item, you can back-probe the connector as well. Connect the meter probes to terminals 'A' and 'B' on the connector.

Turn on the ignition to read the TPS output voltage at the idle position. The reading should be 0.54VDC +/- 0.07VDC. The ideal is the center of the range, 0.54VDC for a stock engine. To adjust the output voltage, loosen the two Torx screws holding the TPS to the throttle body, and slightly rotate the TPS up or down, reading the voltage until it comes into specification. Tighten screws. Using the throttle lever, rotate the throttle to WOT (wide open throttle). The TPS voltage should be over 4.0 volts. Close the throttle again, and then slowly open it to WOT, observing the voltage reading. It should increase progressively and in a linear fashion. If it sticks or jumps or falls off at all while doing this check, the TPS sensor may be failing and could be a cause of stumbling and driveability problems.

After achieving the desired setting, turn off the ignition switch. Remove all jumpers or the scanner and reconnect the TPS connector as required.

Throttle Minimum Air Position

Tools needed:

1. Torx driver # T-20

2. Paper Clip

3. Small Punch

4. Tachometer

GENERAL NOTE: The engine should be at normal operating temperature before performing any adjustments. Never rely on the dash mounted instruments for diagnostics and adjustments. The oil pressure and temperature gauges and the voltmeter and tachometer just aren't calibrated accurately enough for diagnosis, but are a relative indication for monitoring the vehicle while driving.

For this adjustment, the transmission will be in DRIVE while you're under the hood. You will need to securely set the parking brake and block the drive wheels. It would also be a good idea to have an assistant hold the service brake while you perform the adjustments.

In order to successfully complete the adjustment, the IAC air passages and pintle need to be clean. The throttle plates and bores need to be clean as well. If this is not the case, you'll need to remove the air cleaner from TBI engines or the intake air bellows from TPI engines to gain access to the area to be cleaned. A spray-type carburetor cleaner works well for this. Cleaning the IAC passages on a TPI/MAF engine will set a DTC, but we'll be clearing that later. With the engine idling, direct the spray cleaner in to the IAC air passages and around the throttle plates. Shut off the engine and continue cleaning the throttle plates by opening the throttle manually. Once everything is satisfactorily cleaned, replace the air bellows on TPI engines. Many times, this alone can solve IAC/idle speed problems.

Cut and form a paper clip into a "U" shape. Insert the clip ends into the ALDL in the 'A' and 'B' sockets. Turn on the ignition, but don't start the engine. This will force the ECM into its diagnostic mode. Wait 30 seconds to allow the IAC pintle to fully extend. Under the hood, remove the electrical connector from the IAC, then turn off the ignition and remove the paper clip jumper from the ALDL. With the IAC pintle fully extended (closed) all idle air will be controlled by the position of the throttle plates.

Locate the Torx screw on the left side of the throttle body. It may be equipped with a protective metal cap from the factory. This was intended to discourage adjustment. If the cap is present, use a small punch to knock it out. Once the screw is accessible, start the engine and place the transmission in DRIVE. Adjust the throttle stop to obtain 450-500 RPM with the transmission in "DRIVE", rotating the Torx screw clockwise to raise speed and counter-clockwise to lower speed. Once the idle RPM is set, place the transmission in PARK and turn off the engine.

Re-connect the electrical connector onto the IAC. Start engine. Idle speed should be governed by the ECM at approximately 650 rpm in "DRIVE" (for unmodified cars). Idle speed in NEUTRAL or PARK is less significant, and will be higher.

Reinitializing the ECM

If you set a DTC during the procedure, the SES light should be illuminated on the dash. This ECM retains DTC data for the previous 50 engine starts, so the codes will eventually be cleared. If you want more immediate results, after shutting down the engine disconnect the negative battery terminal for five minutes. This will clear the ECM of all diagnostic trouble codes. Clearing the ECM also clears any data learned about your engine, and clears the radio presets. If you have a Delco-Loc or Theft Loc II radio, make sure you follow the procedure to unlock the radio protection before disconnecting the battery. This five minutes is also just about long enough to clean both battery cables. Reconnect the battery. When you first start the engine after clearing the ECM, the engine will operate with base parameters programmed into the ECM PROM. These parameters may not be optimum for your engine, but the ECM will enter a Block Learn Mode soon after the engine is warm and enters Closed Loop Mode. The ECM will write new data tables specific to your engine and will eventually rely on those tables instead of the base tables of the factory program. You can expedite this process by driving the car for 20 minutes under varying conditions to allow the ECM to initialize. Or you can wait and drive the car normally at your convenience. The BLM tables are constantly being updated as sensor input ranges change, but the greatest change will occur within the first twenty minutes of Closed Loop operation.

------------------

Later,

Vader

------------------

"I cannot take this any more... Saying everything I've said before..."

Adobe Acrobat Reader 4.0

First, the MAF might still be functioning, but might not be reporting correctly to the ECM. If you substantially change the airflow pattern through the MAF body, the air flowing through the sampling tube may not be in correct proportion to the total air flowing through the housing. This has been the subject of many "Code 34" posts following a MAF modification. The intake air will follow the path of least resistance, and that might not be through the sampling tube if the screens are altered or the intake ducts are changed to alter the air flow path.

Second, the IAC should still be installed in the throttle body to set minimum air, but the electrical connector needs to be removed from the IAC after the stepper motor has been driven to the fully-closed position. Since you've moved the throttle stop screw and altered the intake air, you should set both the minimum idle air position and TPS setting. If you can't get the engine to idle long enough to do this, have an assistant crank the engine while you manipulate the throttle valve by hand under the hood. The engine needs to be fully warmed to get the correct adjustment, so you might be tweaking the throttle for a while until it will run by itself and is warm enough. The correct procedure is as follows:

Throttle Position Sensor (TPS)

Tools needed:

1. Digital Volt-Ohm-Meter (VOM)

2. Breakout jumper wires or probes (make your own)

3. AutoXray, Diacom, or similar scanner will replace the VOM and jumper wires.

Turn on ignition, but don't start the engine.

With a diagnostic scanner: plug in the scanner and read the TPS voltage. It should be 0.54Volts +/- 0.07 VDC.

Connect the VOM to the TPS electrical connector terminals ‘A' and ‘B'.

With a breakout jumper: Disconnect the electrical connector from the TPS. Install the breakout in-line, between the TPS and wiring harness connector. Connect the meter probes to terminals 'A' and 'B' on the connector. (‘B' is the positive connection, ‘A' the signal ground, or negative.)

With probes: If you have very slender probes on your VOM, you can back-probe the TPS connector while it is attached to the TPS. If you have made probes of large dressmakers pins or a similar item, you can back-probe the connector as well. Connect the meter probes to terminals 'A' and 'B' on the connector.

Turn on the ignition to read the TPS output voltage at the idle position. The reading should be 0.54VDC +/- 0.07VDC. The ideal is the center of the range, 0.54VDC for a stock engine. To adjust the output voltage, loosen the two Torx screws holding the TPS to the throttle body, and slightly rotate the TPS up or down, reading the voltage until it comes into specification. Tighten screws. Using the throttle lever, rotate the throttle to WOT (wide open throttle). The TPS voltage should be over 4.0 volts. Close the throttle again, and then slowly open it to WOT, observing the voltage reading. It should increase progressively and in a linear fashion. If it sticks or jumps or falls off at all while doing this check, the TPS sensor may be failing and could be a cause of stumbling and driveability problems.

After achieving the desired setting, turn off the ignition switch. Remove all jumpers or the scanner and reconnect the TPS connector as required.

Throttle Minimum Air Position

Tools needed:

1. Torx driver # T-20

2. Paper Clip

3. Small Punch

4. Tachometer

GENERAL NOTE: The engine should be at normal operating temperature before performing any adjustments. Never rely on the dash mounted instruments for diagnostics and adjustments. The oil pressure and temperature gauges and the voltmeter and tachometer just aren't calibrated accurately enough for diagnosis, but are a relative indication for monitoring the vehicle while driving.

For this adjustment, the transmission will be in DRIVE while you're under the hood. You will need to securely set the parking brake and block the drive wheels. It would also be a good idea to have an assistant hold the service brake while you perform the adjustments.

In order to successfully complete the adjustment, the IAC air passages and pintle need to be clean. The throttle plates and bores need to be clean as well. If this is not the case, you'll need to remove the air cleaner from TBI engines or the intake air bellows from TPI engines to gain access to the area to be cleaned. A spray-type carburetor cleaner works well for this. Cleaning the IAC passages on a TPI/MAF engine will set a DTC, but we'll be clearing that later. With the engine idling, direct the spray cleaner in to the IAC air passages and around the throttle plates. Shut off the engine and continue cleaning the throttle plates by opening the throttle manually. Once everything is satisfactorily cleaned, replace the air bellows on TPI engines. Many times, this alone can solve IAC/idle speed problems.

Cut and form a paper clip into a "U" shape. Insert the clip ends into the ALDL in the 'A' and 'B' sockets. Turn on the ignition, but don't start the engine. This will force the ECM into its diagnostic mode. Wait 30 seconds to allow the IAC pintle to fully extend. Under the hood, remove the electrical connector from the IAC, then turn off the ignition and remove the paper clip jumper from the ALDL. With the IAC pintle fully extended (closed) all idle air will be controlled by the position of the throttle plates.

Locate the Torx screw on the left side of the throttle body. It may be equipped with a protective metal cap from the factory. This was intended to discourage adjustment. If the cap is present, use a small punch to knock it out. Once the screw is accessible, start the engine and place the transmission in DRIVE. Adjust the throttle stop to obtain 450-500 RPM with the transmission in "DRIVE", rotating the Torx screw clockwise to raise speed and counter-clockwise to lower speed. Once the idle RPM is set, place the transmission in PARK and turn off the engine.

Re-connect the electrical connector onto the IAC. Start engine. Idle speed should be governed by the ECM at approximately 650 rpm in "DRIVE" (for unmodified cars). Idle speed in NEUTRAL or PARK is less significant, and will be higher.

Reinitializing the ECM

If you set a DTC during the procedure, the SES light should be illuminated on the dash. This ECM retains DTC data for the previous 50 engine starts, so the codes will eventually be cleared. If you want more immediate results, after shutting down the engine disconnect the negative battery terminal for five minutes. This will clear the ECM of all diagnostic trouble codes. Clearing the ECM also clears any data learned about your engine, and clears the radio presets. If you have a Delco-Loc or Theft Loc II radio, make sure you follow the procedure to unlock the radio protection before disconnecting the battery. This five minutes is also just about long enough to clean both battery cables. Reconnect the battery. When you first start the engine after clearing the ECM, the engine will operate with base parameters programmed into the ECM PROM. These parameters may not be optimum for your engine, but the ECM will enter a Block Learn Mode soon after the engine is warm and enters Closed Loop Mode. The ECM will write new data tables specific to your engine and will eventually rely on those tables instead of the base tables of the factory program. You can expedite this process by driving the car for 20 minutes under varying conditions to allow the ECM to initialize. Or you can wait and drive the car normally at your convenience. The BLM tables are constantly being updated as sensor input ranges change, but the greatest change will occur within the first twenty minutes of Closed Loop operation.

------------------

Later,

Vader

------------------

"I cannot take this any more... Saying everything I've said before..."

Adobe Acrobat Reader 4.0

Last edited by Vader; 03-31-2018 at 09:50 AM. Reason: Updated links

#9

Supreme Member

Thread Starter

Join Date: Feb 2000

Location: Seattle, Washington

Posts: 1,170

Likes: 0

Received 0 Likes

on

0 Posts

Car: '87 IROC-Z/'82 RX7

Engine: SBC 355/1.1L Rotary

Transmission: T56/5 Speed

Axle/Gears: 4.33/3.93

I think I have the IAC back to normal now. However, I don't have a VOM or a scanner. Which means I'll be heading to the late night auto parts store. It idles at 900 nue and 600 drive. I think it's okay. I'll check the TPS to be sure. Thanks. I know you've all repeated this hundreds of times. And Vader you are definatly the expert. I feel rather dumb because of all this, but I guess you live and learn. Thanks again.

#10

Red,

Incidentally, if you have the "garbage can" air cleaner (the round one) you can't cut holes in the outer wall of the housing to admit more air. These air cleaners flow air from the inside of the filter to the outside, so cutting "windows" in the outer walls will admit hot, unfiltered underhood air to the engine instead of filtered air.

I've got the same cleaner on my '86 and almost did the same thing until I realized that the air flows "backwards: from what I expected. What's worse, TPIS Insider Hints lists this as a performance modification, but mentions nothing about the complete bypass of the air filter element on this type of air cleaner. Pretty scary that such a "reliable" source would miss that one, huh?

------------------

Later,

Vader

------------------

"I cannot take this any more... Saying everything I've said before..."

Adobe Acrobat Reader 4.0

Incidentally, if you have the "garbage can" air cleaner (the round one) you can't cut holes in the outer wall of the housing to admit more air. These air cleaners flow air from the inside of the filter to the outside, so cutting "windows" in the outer walls will admit hot, unfiltered underhood air to the engine instead of filtered air.

I've got the same cleaner on my '86 and almost did the same thing until I realized that the air flows "backwards: from what I expected. What's worse, TPIS Insider Hints lists this as a performance modification, but mentions nothing about the complete bypass of the air filter element on this type of air cleaner. Pretty scary that such a "reliable" source would miss that one, huh?

------------------

Later,

Vader

------------------

"I cannot take this any more... Saying everything I've said before..."

Adobe Acrobat Reader 4.0

#11

Supreme Member

Thread Starter

Join Date: Feb 2000

Location: Seattle, Washington

Posts: 1,170

Likes: 0

Received 0 Likes

on

0 Posts

Car: '87 IROC-Z/'82 RX7

Engine: SBC 355/1.1L Rotary

Transmission: T56/5 Speed

Axle/Gears: 4.33/3.93

Hey Vader.... I've got the snorkel with 2 square air filters. I just cut the bottom of the box UNDER the air filters. I made sure I had air flow from filter, untouched to the Throttle Body.

I know that in books.... everything on the '85, is backward from the '86. Like the battery for instance, is on the right hand side, I believe, on the '86. It's weird that much I know. Now either my VIN is WAY OFF and I don't really have an '85 z28... or something else is goin' on.

[This message has been edited by ReDnEk27 (edited January 11, 2001).]

I know that in books.... everything on the '85, is backward from the '86. Like the battery for instance, is on the right hand side, I believe, on the '86. It's weird that much I know. Now either my VIN is WAY OFF and I don't really have an '85 z28... or something else is goin' on.

[This message has been edited by ReDnEk27 (edited January 11, 2001).]

#12

Red,

My understanding is that there was a change in mid-year for TPI engines. THe early TPIs used the older 8-bit ECM preocessor which couldn't function well enough to meet 1986 EPA standards. Because of this, the Delco digital MAF was dropped in mid-year and the Bosch analog MAF with 16-bit Delco ECM processor was used on the few TPIs produced after the change (like the '86s). You might have one of those few late '85 TPIs. If you have the analog Bosch MAF, there's little question about it.

Both '85 and '86 are somewhat odd years, and the '86 I have is a real bastard-child of the line.

------------------

Later,

Vader

------------------

"I cannot take this any more... Saying everything I've said before..."

Adobe Acrobat Reader 4.0

My understanding is that there was a change in mid-year for TPI engines. THe early TPIs used the older 8-bit ECM preocessor which couldn't function well enough to meet 1986 EPA standards. Because of this, the Delco digital MAF was dropped in mid-year and the Bosch analog MAF with 16-bit Delco ECM processor was used on the few TPIs produced after the change (like the '86s). You might have one of those few late '85 TPIs. If you have the analog Bosch MAF, there's little question about it.

Both '85 and '86 are somewhat odd years, and the '86 I have is a real bastard-child of the line.

------------------

Later,

Vader

------------------

"I cannot take this any more... Saying everything I've said before..."

Adobe Acrobat Reader 4.0

#13

Senior Member

Join Date: Nov 2000

Location: Richmond, VA

Posts: 798

Likes: 0

Received 0 Likes

on

0 Posts

Nice sig change Vader, straight from Linkin Park!

------------------

--Steve S-- 84 Trans Am 305 (cough)LG4(cough), 5 speed, Flowmaster 80 series, otherwise an emissions restricted slow 150 hp(chilton rating) 240 torquer that needs RELEASE!!!!

P.S. Daily Driver

------------------

--Steve S-- 84 Trans Am 305 (cough)LG4(cough), 5 speed, Flowmaster 80 series, otherwise an emissions restricted slow 150 hp(chilton rating) 240 torquer that needs RELEASE!!!!

P.S. Daily Driver

#14

Supreme Member

Thread Starter

Join Date: Feb 2000

Location: Seattle, Washington

Posts: 1,170

Likes: 0

Received 0 Likes

on

0 Posts

Car: '87 IROC-Z/'82 RX7

Engine: SBC 355/1.1L Rotary

Transmission: T56/5 Speed

Axle/Gears: 4.33/3.93

With the IAC unplugged, I've got the idle at 400rpm. Now as I go to adjust the TPS, the reading started at 1.24. I can't position it to get a reading lower than .96. What's wrong? Should I back the idle screw out? It's 1.24 with the TPS pointing as vertical as can be, and .96 pointing down as can be. That's the range. Help?

#15

Supreme Member

Thread Starter

Join Date: Feb 2000

Location: Seattle, Washington

Posts: 1,170

Likes: 0

Received 0 Likes

on

0 Posts

Car: '87 IROC-Z/'82 RX7

Engine: SBC 355/1.1L Rotary

Transmission: T56/5 Speed

Axle/Gears: 4.33/3.93

I went through the IAC and TPS adjust again start to finish. IAC I have down pat. It idles @480 with IAC unplugged. When I attempt to adjust my TPS, it goes from .95 (down ward) to 1.25 (upward). I took the TPS completely off, moved the lever, could not get a reading lower than .95. What do I do? Did I not find DTC on the IAC? I waited for 2 minutes for the pintle to fully retract. OR is my TPS done for?

PS. While in the *learn mode* of the ecm. The car ran PERFECT.

PS. While in the *learn mode* of the ecm. The car ran PERFECT.

#16

Supreme Member

Join Date: Jul 2000

Location: Kempner,TX,

Posts: 1,014

Likes: 0

Received 0 Likes

on

0 Posts

Car: 1996 Vette / 1992 GSX1100F Suzuki

Engine: 1996 Corvette Coupe 388 LT1 (+.060)

Transmission: Auto

Axle/Gears: 3.07

Are you taking your voltage readings from terminals A and B (Top and Center) of the TPS? Terminal "C" (the lower one) is reference voltage only and isn't used in setting the TPS voltage.

Jumpering the A and B terminals of the ALDL then turning the ignition key to "ON" should cause the IAC pintle to extend to it's fully closed position, not retract. Also, with the pintel fully extended it should not be extended beyond a certain length.

I'd have to look up the exact maximum extension in my manual to be sure of the length. Maybe someone can post it for you; if not I'll post it later today.

Jake

------------------

1986 Corvette Coupe, 415 CID, Edelbrock 6073s, ZZ9

Jumpering the A and B terminals of the ALDL then turning the ignition key to "ON" should cause the IAC pintle to extend to it's fully closed position, not retract. Also, with the pintel fully extended it should not be extended beyond a certain length.

I'd have to look up the exact maximum extension in my manual to be sure of the length. Maybe someone can post it for you; if not I'll post it later today.

Jake

------------------

1986 Corvette Coupe, 415 CID, Edelbrock 6073s, ZZ9

#17

Supreme Member

Join Date: Jul 2000

Location: Kempner,TX,

Posts: 1,014

Likes: 0

Received 0 Likes

on

0 Posts

Car: 1996 Vette / 1992 GSX1100F Suzuki

Engine: 1996 Corvette Coupe 388 LT1 (+.060)

Transmission: Auto

Axle/Gears: 3.07

If you suspect the absence of the screens in the MAF is causing the problem, why not replace them with screen from your local hardware store.

The screen can be wrapped around the OD of the MAF at both ends, and held in place by the clamps or heavy rubber bands.

Temporary use will serve to eliminate the screens as a possible cause and would be a lot cheaper than buying a new MAF only to find it makes no difference.

Jake

------------------

1986 Corvette Coupe, 415 CID, Edelbrock 6073s, ZZ9

The screen can be wrapped around the OD of the MAF at both ends, and held in place by the clamps or heavy rubber bands.

Temporary use will serve to eliminate the screens as a possible cause and would be a lot cheaper than buying a new MAF only to find it makes no difference.

Jake

------------------

1986 Corvette Coupe, 415 CID, Edelbrock 6073s, ZZ9

#18

Supreme Member

Thread Starter

Join Date: Feb 2000

Location: Seattle, Washington

Posts: 1,170

Likes: 0

Received 0 Likes

on

0 Posts

Car: '87 IROC-Z/'82 RX7

Engine: SBC 355/1.1L Rotary

Transmission: T56/5 Speed

Axle/Gears: 4.33/3.93

I could only get to the rear screen of the MAF sensor, and removed it. That is beyond the sampling tube of the MAF following air flow. It *shouldn't* be causing problems. My problem here is, that I have it set to minimun air like instructed. Fully instructed.

The trouble is with setting the TPS. I am checking A and B terminals with a new volt meter. I can't get a reading lower than .93 at ANY angle. After running the closed loop.. I think it is... the car idles at 1500 and in drive at 900.

So I'm at a loss for anything here. Yall wanna post to help cause I don't have the cash to take it to a damned mechanic. If I can't get it solved this afternoon, I've already planned to port the plenum, I'm jsut gonna go into that, then when I put **** back on, re-calibrate it and hope it works.

The trouble is with setting the TPS. I am checking A and B terminals with a new volt meter. I can't get a reading lower than .93 at ANY angle. After running the closed loop.. I think it is... the car idles at 1500 and in drive at 900.

So I'm at a loss for anything here. Yall wanna post to help cause I don't have the cash to take it to a damned mechanic. If I can't get it solved this afternoon, I've already planned to port the plenum, I'm jsut gonna go into that, then when I put **** back on, re-calibrate it and hope it works.

#19

Red,

The TPS voltage should vary from about 1/2VDC at idle to at least 4.0VDC at WOT. Even if the sensor is indicating 0.93V at the idle position, it should STILL indicate at least 4V at the WOT position. If the voltage doesn't vary that much there is a strong possibility that the TPS is failing.

Of course, you are checking on a DC voltage scale and with the probes in the correct jacks on the meter, right?

------------------

Later,

Vader

------------------

"I cannot take this any more... Saying everything I've said before..."

Adobe Acrobat Reader 4.0

The TPS voltage should vary from about 1/2VDC at idle to at least 4.0VDC at WOT. Even if the sensor is indicating 0.93V at the idle position, it should STILL indicate at least 4V at the WOT position. If the voltage doesn't vary that much there is a strong possibility that the TPS is failing.

Of course, you are checking on a DC voltage scale and with the probes in the correct jacks on the meter, right?

------------------

Later,

Vader

------------------

"I cannot take this any more... Saying everything I've said before..."

Adobe Acrobat Reader 4.0

#20

Supreme Member

Thread Starter

Join Date: Feb 2000

Location: Seattle, Washington

Posts: 1,170

Likes: 0

Received 0 Likes

on

0 Posts

Car: '87 IROC-Z/'82 RX7

Engine: SBC 355/1.1L Rotary

Transmission: T56/5 Speed

Axle/Gears: 4.33/3.93

It's on the 20VDC setting. The probes are in the right terminals. I've checked this over many times. At WOT it only goes up to about 2.25. Should I go down and pick up a new TPS and see if I get better results?

#21

Supreme Member

Thread Starter

Join Date: Feb 2000

Location: Seattle, Washington

Posts: 1,170

Likes: 0

Received 0 Likes

on

0 Posts

Car: '87 IROC-Z/'82 RX7

Engine: SBC 355/1.1L Rotary

Transmission: T56/5 Speed

Axle/Gears: 4.33/3.93

IT WORKS IT WORKS VICTORY IS MINE! NEW TPS RIGHT ON .54! EXCELLENTE! Idle purrs like a kitty. I'd like to thank my friends, family, Vader, and all the others whom helped this be a possibility. Oh and GI JOES for having a TPS for 33$ rather than Napa's 48 and what ever sky rocket the dealer's is. THANKS!!!!!!!!!!

#22

Red,

Kewl! That's a pretty phreaky thing, having hte TPS go bye-bye right after removing the MAF screen and air box mods. Makes you think there's some kind of dark force at work under the hood....

------------------

Later,

Vader

------------------

"I cannot take this any more... Saying everything I've said before..."

Adobe Acrobat Reader 4.0

Kewl! That's a pretty phreaky thing, having hte TPS go bye-bye right after removing the MAF screen and air box mods. Makes you think there's some kind of dark force at work under the hood....

------------------

Later,

Vader

------------------

"I cannot take this any more... Saying everything I've said before..."

Adobe Acrobat Reader 4.0

#23

Supreme Member

Thread Starter

Join Date: Feb 2000

Location: Seattle, Washington

Posts: 1,170

Likes: 0

Received 0 Likes

on

0 Posts

Car: '87 IROC-Z/'82 RX7

Engine: SBC 355/1.1L Rotary

Transmission: T56/5 Speed

Axle/Gears: 4.33/3.93

I've got my dad's luck like that. 1 straight forward step, 8 complexities backwards. Thanks again. YOU THE MAN!

Thread

Thread Starter

Forum

Replies

Last Post

1992rs/ss

NW Indiana and South Chicago Suburb

12

05-19-2020 07:02 PM

1992rs/ss

Engine/Drivetrain/Suspension Parts for Sale

16

01-28-2016 09:58 PM